The Different Applications That Channel And Duct Mixers Can Be Used For

Open-channel static mixers are essential components in various industrial water treatment and wastewater treatment applications. Static mixer water treatment facilitates the mixing of fluids, chemicals, and other substances to achieve the desired outcomes, with greater efficiency and consistency than powered mixing technologies.

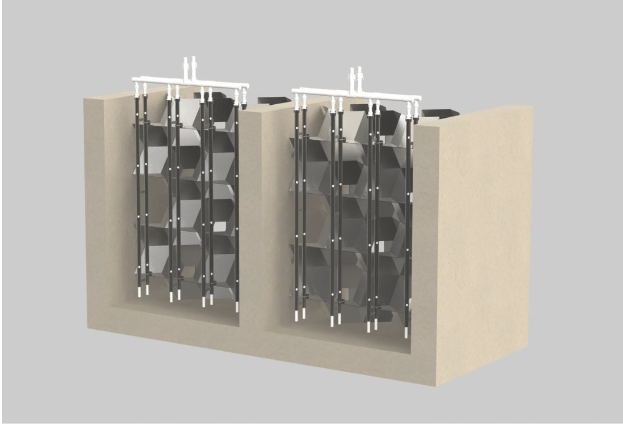

Static mixers blend or mix fluids into a homogenous output by directing water along a channel or duct equipped with a series of fixed elements or baffles placed in the path of the flow. These applications require no moving parts or external energy source, using the kinetic energy of the flow itself to generate the turbulence required to thoroughly mix the additives into the water.

Let’s look at four of the main applications of channel and duct mixers in water treatment plants:

1. Raw Water Blending

The primary source of water for many treatment plants is ‘raw’, or untreated surface water drawn from lakes, rainwater storage tanks, rivers, the sea, or reservoirs. The quality of this raw water can vary significantly depending on various factors, such as the local environment, industrial and domestic activity, the surrounding rock and soil profile, and weather conditions.

‘Raw water blending’ involves mixing different sources of raw water to achieve a target uniform quality that meets the standards needed for your application. Channel mixers are ideal for this process, helping to evenly distribute any variations in water quality and creating consistency throughout the treatment process. Using a series of membranes, channel mixers generate a strong tidal wave that pushes through the channel or duct, creating water without sediment or crust.

2. Rapid Coagulant Addition

Coagulant addition is the process of adding coagulant chemicals (e.g. polyamines, melamine formaldehyde resin, biopolymers like chitosan, polyDADMAC etc) to a large volume of soiled or contaminated water (e.g. greywater, industrial process water, or sewage) to ‘destabilise’ soluble particles and facilitate their removal.

The speed at which these chemicals are added is essential for achieving the right level of coagulation and preventing undesirable byproducts from forming. Usually, this has to be carried out quickly, so for rapid coagulant addition, you’ll need a channel mixer with high mixing intensity and a short mixing time, quickly and thoroughly distributing your coagulant to achieve effective particle destabilisation.

3. Polyelectrolyte Dosing

In some applications (e.g. when treating highly turbid waters, for dewatering sludge, or when traditional coagulants are insufficient to achieve your required level of clarity), additional polyelectrolytes are used to enhance the coagulation or flocculation process. These additives help to improve floc formulation and increase particle removal efficiency. However, to be effective, polyelectrolyte dosing requires extremely precise and controlled mixing to prevent either under-dosing or overdosing – both of which can affect treatment outcomes. Channel static mixers deliver excellent mixing performance, giving you accurate control over your polyelectrolyte dosing for optimal results.

4. pH Control

Many of the chemical reactions used in water treatment – such as flocculation and coagulation – are pH-dependent. Some applications, therefore, call for additional acidic or base (alkaline) substances to adjust the pH of the process water to within a specific range. This is essential, for instance, for preventing corrosion of plant equipment and plumbing, preventing scaling, and for thorough disinfection. When coupled with an automated dosing system and feedback controls, a static mixer water treatment system is an effective way of achieving consistent pH levels across the plant, mixing the acid or alkaline chemicals uniformly with the water.

Find Out More

To find out more about our range of static mixers or to speak with one of our experienced team about which mixing technology is best for your applications, please contact us today by clicking here.