Does a Static Mixer Need Regular Maintenance? Your Questions Answered

Industrial static mixers have revolutionised fluid processing, offering unparalleled efficiency without the disruption and cost of regular maintenance. With a simple design that doesn’t rely on moving parts, static mixers are the failsafe choice for businesses that need to trim their operational costs, increase uptime, and achieve greater reliability.

In this article, we’ll answer the key questions about static mixers and the maintenance involved.

Q. How Do Static Mixers Work?

To understand the maintenance requirements of static mixers, it is important to understand how they work.

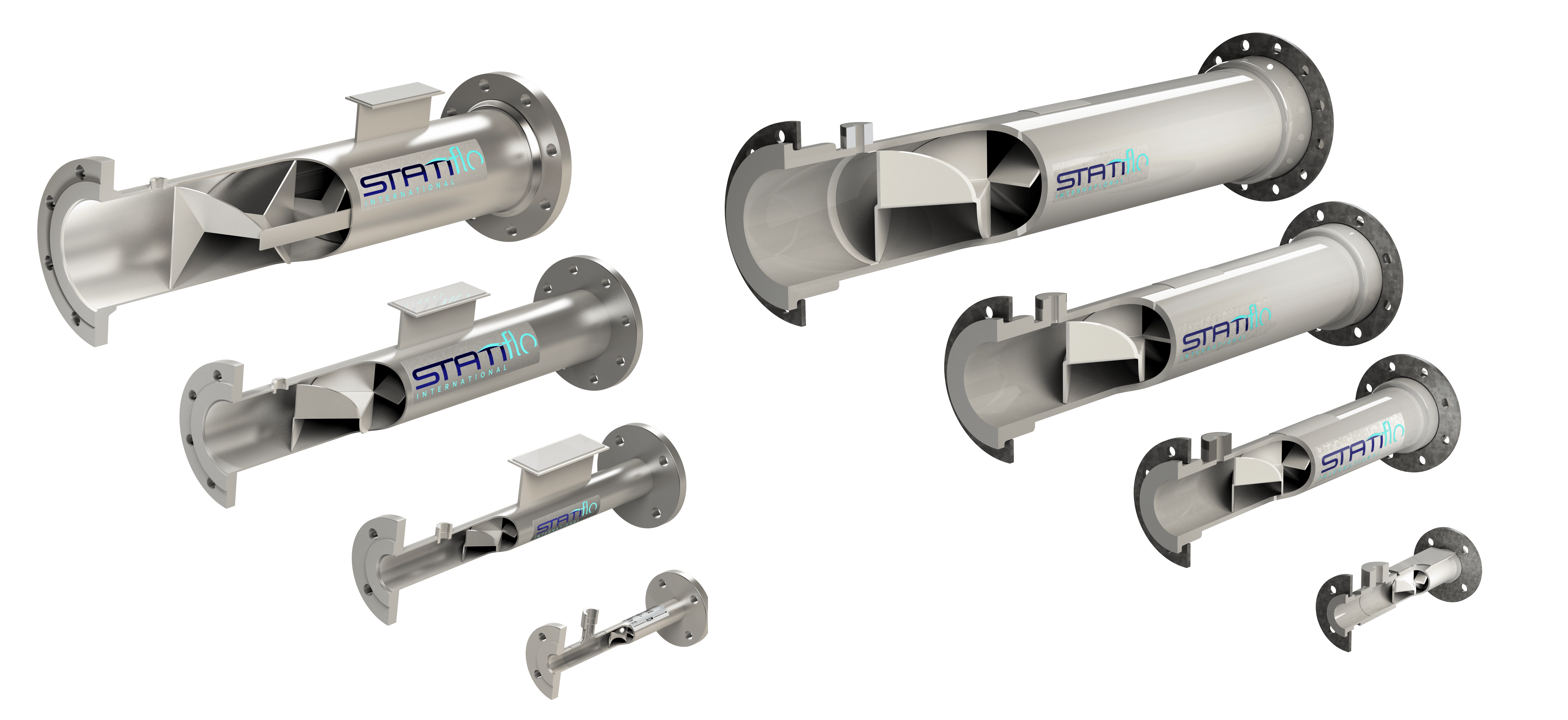

Static mixers manipulate fluid flow without moving parts, relying instead on precisely engineered components inside a pipe or container, such as plates, baffles, or channels. As fluids pass through these components, they are divided, twisted, and recombined. The turbulent movement ensures thorough blending, the even distribution of components, and homogenisation within the fluid.

Q. What are the Benefits of Minimal Maintenance?

One of the key benefits of static mixers is that they require minimal maintenance or repairs. Unlike traditional mixers with complex mechanical components, static mixers have no moving parts, significantly reducing wear and tear and the potential for mechanical failure. Because of the simple design of static mixers, it isn’t necessary to conduct frequent inspections, lubrication, or replacement components, which results in significant cost savings and increased operational uptime.

Q. How Much Space for Static Mixers is Needed?

When deciding where to position static mixers, they offer exceptional versatility, particularly because they don’t need to be easily accessible for regular maintenance. Their minimal maintenance requirements allow them to be installed in restricted spaces where traditional stirred-tank mixers might not fit. Because of their adaptability, static mixers suit various industries, ensuring effective mixing even in compact or challenging environments without compromising performance.

Q. Is Contamination a Risk When Maintaining Static Mixers?

Static pipe mixers utilise a completely enclosed design, eliminating the need for shaft seals found in stirred tanks. A closed system significantly reduces the risk of contamination, ensuring a cleaner process without the need for seal inspections or replacements. As well as reducing maintenance costs and system downtime, the enclosed design of static mixers also reduces potential contamination, allowing for consistent and reliable operation.

Contact us for Expert Advice

If you have any questions about static mixers, how they work, and how they should be maintained, please get in touch with our experts at Statiflo today.