From Low Maintenance To No Maintenance With Sanitary Static Mixers

Industrial static mixers come in many different designs and specifications, so it’s crucial to select the model that most suits your intended application. Stainless steel static mixers play a crucial role in pharmaceuticals and food production by blending ingredients thoroughly to ensure consistent quality while maintaining exceptional hygiene and cleanliness of production equipment.

In this article, we’ll explain how sanitary static mixers deliver exceptional performance and results without requiring expensive and time-consuming maintenance.

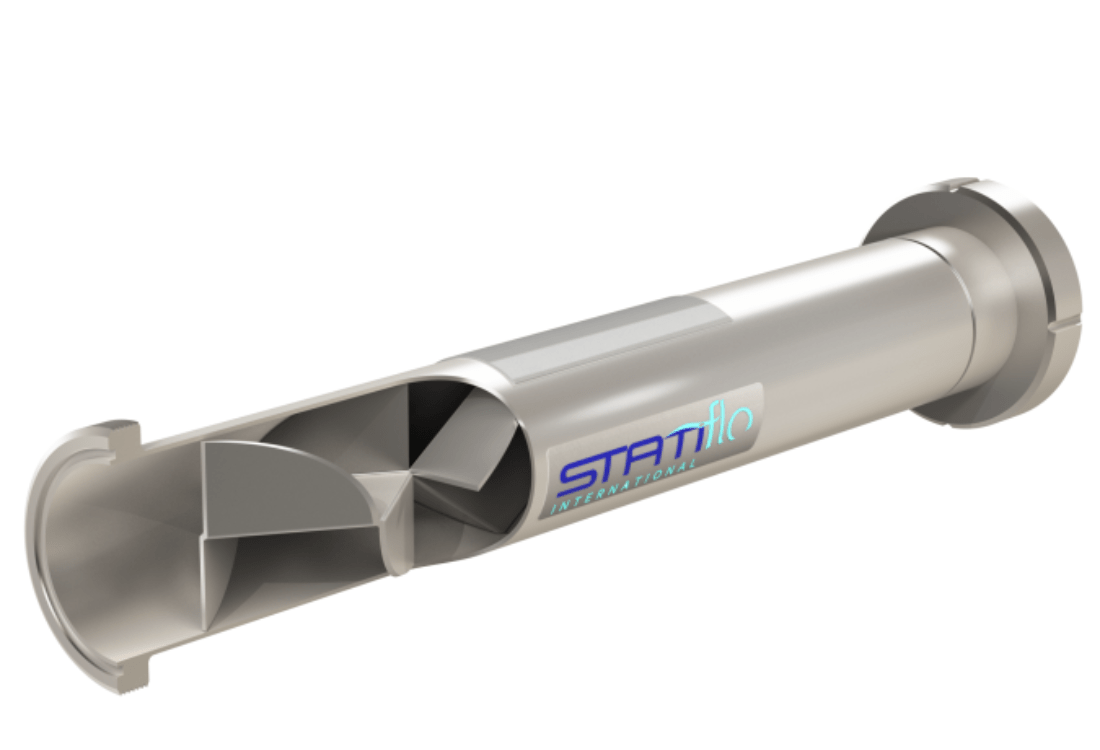

No Moving Parts

Unlike traditional stirred tank mixers, which rely on complex mechanical components that are prone to wear and tear, sanitary static mixers have no internal moving parts. This means that they require no regular maintenance, parts replacement, or time-consuming servicing; instead, plant managers can be assured of consistent, reliable service, free from disruptive and costly downtime and the expense of replacement parts.

Uncomplicated Design

Sanitary static mixers feature a straightforward design that, typically, comprises a series of baffles, elements, or channels configured within a housing or pipe. The minimalistic structure not only ensures reliable operation but also simplifies potential maintenance tasks: the absence of complex or intricate components results in fewer opportunities for malfunctions and a simpler, less time-consuming, and cheaper approach to maintenance.

CIP And SIP Capabilities

Because they are used in the food and drink and pharmaceutical industries, it’s critical that static mixers comply with stringent safety regulations and help to ensure that manufacturing processes are safe for end-consumers. Sanitary static mixers often incorporate Clean-in-Place (CIP) and Sterilise-in-Place (SIP) procedures, which facilitate effective cleaning and sterilisation without the need for disassembly. CIP and SIP deliver effortless maintenance routines that maximise operational uptime without compromising on the quality or depth of cleaning.

Exceptional Efficiency

Sanitary static mixers are highly regarded, not only for their easy maintenance but also their efficiency, particularly their ability to produce a greater volume of on-spec products while consuming less energy. The result? Invaluable cost savings and a lower environmental impact which aligns with your business’s commitment to sustainable operations.

Contact Us To Find Out More

Incorporating sanitary static mixers into industrial processes is a strategic decision that yields tangible benefits. To find out more about our range of sanitary static mixers, please get in touch today.