How Could A Static Pipe Mixer Aid In The Desalination Process?

Global water shortages are becoming an increasingly prevalent problem, with at least one-half of the world’s population facing shortfalls for at least one month every year, according to the United Nations. Therefore, the importance of desalination should not be underestimated. A process that removes salts and minerals from saline water, desalination ensures that water is suitable for human consumption, irrigation, and industrial use. With nearly 2 billion people facing ‘absolute water scarcity’ by 2025, desalination offers a viable solution to meet the increasing demand for fresh water.

In this article, we’ll explain the critical role that a pipe static mixer plays in the desalination process.

The Importance Of Chemical Treatment

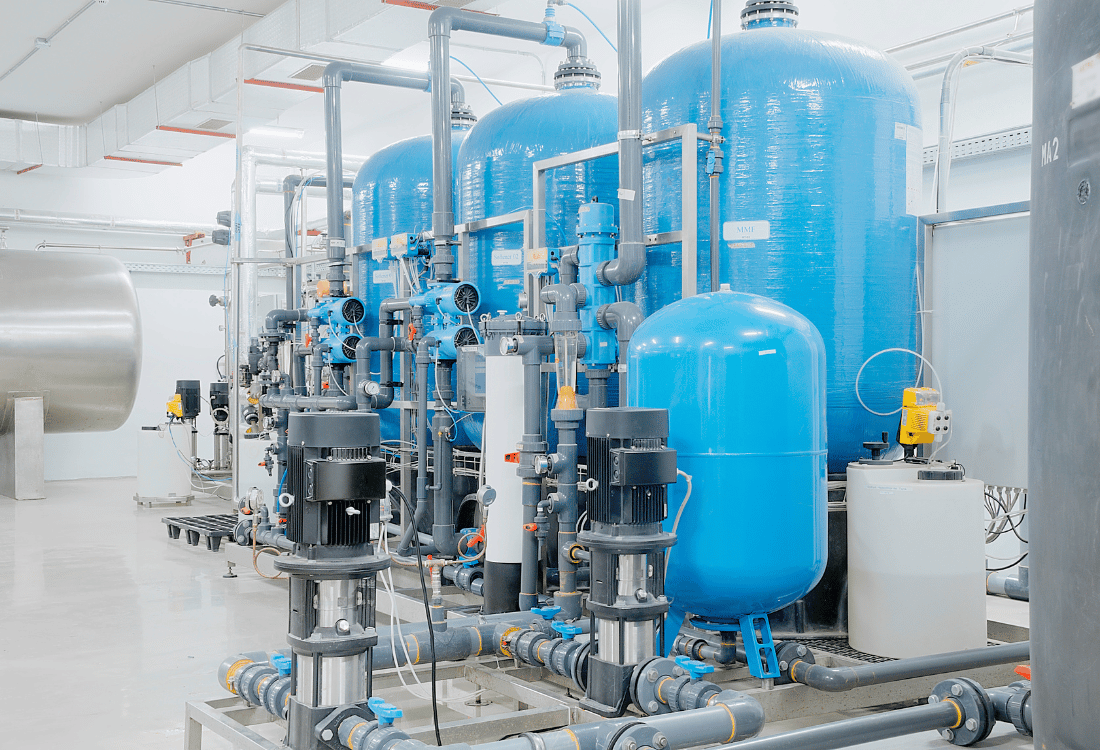

Desalination plants rely on various pre- and post-treatment processes to ensure that the water meets the required quality standards. These processes often involve the addition of chemicals, such as coagulants, flocculants, and disinfectants, which need to be thoroughly mixed with the water to achieve optimum performance and the desired water quality. A pipe static mixer is crucial in this process.

What Is A Pipe Static Mixer?

A pipe static mixer is a motionless device installed within a pipe system that promotes efficient mixing and blending of fluids without the need for an external energy source or moving parts. By creating a series of flow divisions and radial mixing elements, a static mixer generates a highly turbulent flow pattern, ensuring complete mixing and homogenisation of the chemicals with the water. With no moving parts, static mixers require little in the way of ongoing maintenance and are highly reliable, as they are not prone to wear and tear.

Optimising Chemical Dosing

A key advantage of using a pipe static mixer in the desalination process is its ability to optimise chemical dosing in pre-treatment processes. Proper chemical dosing is essential to ensure that water quality meets regulatory standards while minimising the risk of overdosing or underdosing. A static mixer guarantees uniform distribution of chemicals throughout the water stream, leading to more effective treatment and potential cost savings by reducing excessive chemical usage.

Ensuring Effective Post-Treatment Processes

Furthermore, static mixers play a vital role in post-treatment processes, such as pH adjustment, remineralisation, and corrosion control, processes which often rely on the addition of chemicals to enhance the overall water quality and prevent health risks to consumers. By ensuring thorough mixing and uniform distribution of chemicals, static mixers contribute to the optimisation of the post-treatment process, resulting in consistent high-quality water.

Delivering Reverse Osmosis Desalination

In Reverse Osmosis (RO) desalination systems, which are widely used for seawater and brackish water treatment, static mixers can be utilised to optimise water distribution across the RO membrane modules. As well as enhancing the efficiency of the RO process, this also prolongs the lifespan of the membranes, reducing maintenance and replacement costs.

Find Out More About Our Static Mixers For Water Treatment

As a global static mixer manufacturer with a reputation for excellence, we can provide professional advice about how our static mixes can improve your industrial processes. To find out more, please get in touch today.

Image Source: Canva