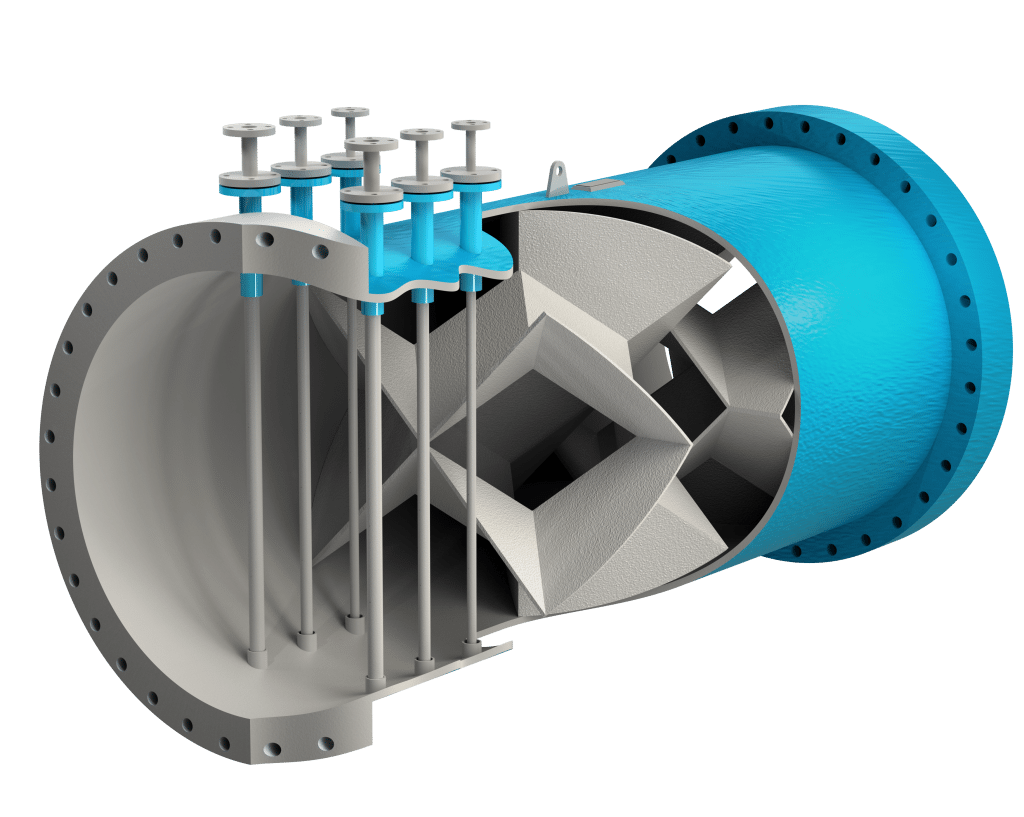

Fiberglass industrial static mixers, often made from Glass Reinforced Plastic (GRP) or Fiberglass Reinforced Plastic (FRP), are essential components in various industries due to their durability and corrosion resistance. These mixers are particularly advantageous in challenging environments, such as desalination facilities and wastewater treatment plants, where corrosive fluids are often conveyed.

Blog

Posts about Industrial static mixer (3):

Subscribe to our blog

Posts By Topics

- Industrial static mixer (26)

- Water Treatment Static Mixers (19)

- Static Mixer (10)

- Pipe Static Mixers (6)

- Channel And Duct Static Mixers (4)

- Static Inline Mixers (4)

- Pipe Mixers (3)

- Chemical Dosing Lances (2)

- Compact Static Mixers (2)

- Oil And Gas (2)

- Gas Dispersion Systems (1)

- Principles of operation (1)

- Sanitary Mixers (1)

- Static Mixer UK (1)

- Static Mixers (1)

The Different Applications For Which Static Mixers Can Be Used In The Marine Industry

Marine processes are more challenging due to harsh environmental conditions, strict regulations, and the need for efficient use of space and energy. Static mixers, are ideal in marine and offshore settings because they offer reliable,...

The Benefits Of Chemical Dosing Lances in Mixing Processes

Chemical dosing, or injection, lances are an essential tool for ensuring the precise and efficient introduction of chemicals into mixing processes. When integrated withindustrial static mixers, injection lances enhance performance by delivering...

The Use Of Static Mixers In The Wastewater Process

The recent outbreak of Cryptosporidium in Devon, which has resulted in more than 100 cases of waterborne illness, has highlighted the potential risks of contaminants entering the water supply. The cleanliness of water, whether it is fed back into...

Road To Net Zero: Attaining Low Carbon Emissions With Static Mixers

With the UK General Election just weeks away and a change of government likely, many business leaders will be pondering what this will mean for their organisation. Both the Conservatives and Labour share a broad commitment to achieving Net Zero in...

Subscribe to our blog

Posts By Topics

- Industrial static mixer (26)

- Water Treatment Static Mixers (19)

- Static Mixer (10)

- Pipe Static Mixers (6)

- Channel And Duct Static Mixers (4)

- Static Inline Mixers (4)

- Pipe Mixers (3)

- Chemical Dosing Lances (2)

- Compact Static Mixers (2)

- Oil And Gas (2)

- Gas Dispersion Systems (1)

- Principles of operation (1)

- Sanitary Mixers (1)

- Static Mixer UK (1)

- Static Mixers (1)