How The Coagulation and Flocculation Processes Take Place With The Use Of Static Mixers

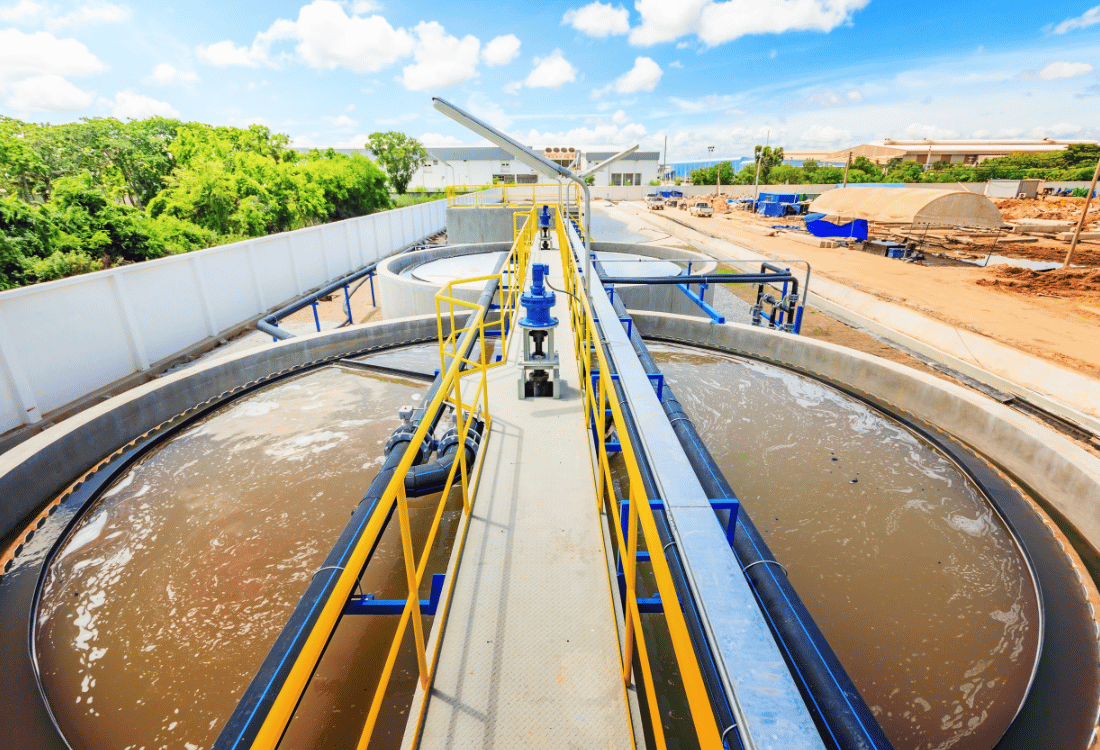

Removing contaminants from water and wastewater is crucial for several reasons: to protect public health, prevent environmental pollution that could damage fragile ecosystems, and ensure safe water for domestic and industrial processes. Coagulation and flocculation are two highly effective ways of removing unwanted contaminants during the wastewater treatment process, particularly when used in tandem. By helping to separate solid contaminants from liquids, coagulation and flocculation ensure that water is clear, hygienic, and safer for consumption.

The effectiveness of these water treatment processes depends on their efficiency, which is where industrial static mixers play a key role. In this article, we’ll explain the processes of coagulation and flocculation, and how static mixers ensure thorough mixing, for clearer, safer water.

What Is Coagulation?

Coagulation is the first step in the water treatment process in which small, destabilised particles in water are combined into larger clumps, known as flocs. This is achieved by adding chemicals - coagulants - to the water which, typically, are metallic salts such as alum or ferric chloride. The coagulants neutralise the charge on the particles, causing them to stick together.

To ensure coagulation is successful, however, the coagulant must be rapidly mixed into the water: typically, a complete mix needs to occur within 5 seconds or less after injection of the coagulant. Rapid mixing helps to maximise the contact between the particles and the coagulant, leading to the formation of microflocs.

What Is Flocculation?

Following coagulation, flocculation further assists in the removal of solids from the water. During this stage, a flocculant, usually a polymer, is introduced into the water which encourages the smaller microflocs from coagulation to combine into larger, denser flocs. Because of their size, these are more easily filtered out or allowed to settle, depending on the separation method to be used.

The flocculation process continues downstream, with the flocs gradually growing in size as the water flows through the treatment system.

What Role Do Static Mixers Play In Coagulation and Flocculation?

Static mixers play a crucial role in ensuring efficient mixing during coagulation and flocculation. Low-shear by design, static mixers effectively mix the chemicals into the water without breaking up the flocs while ensuring even distribution of the coagulant. This is particularly important because flocs are delicate and can easily disintegrate if exposed to excessive turbulence or shear forces, which would make them harder to remove from the water.

The use of static mixers optimises the mixing process, ensuring coagulants are rapidly and thoroughly distributed and flocculants are evenly applied, promoting the formation of large, stable flocs that can be more easily removed through filtration or settling.

Consult The Experts at Statiflo

To find out more about our static mixers and how they can be used in your flocculation processes, please get in touch with the team at Statiflo today!

Image Source: Canva