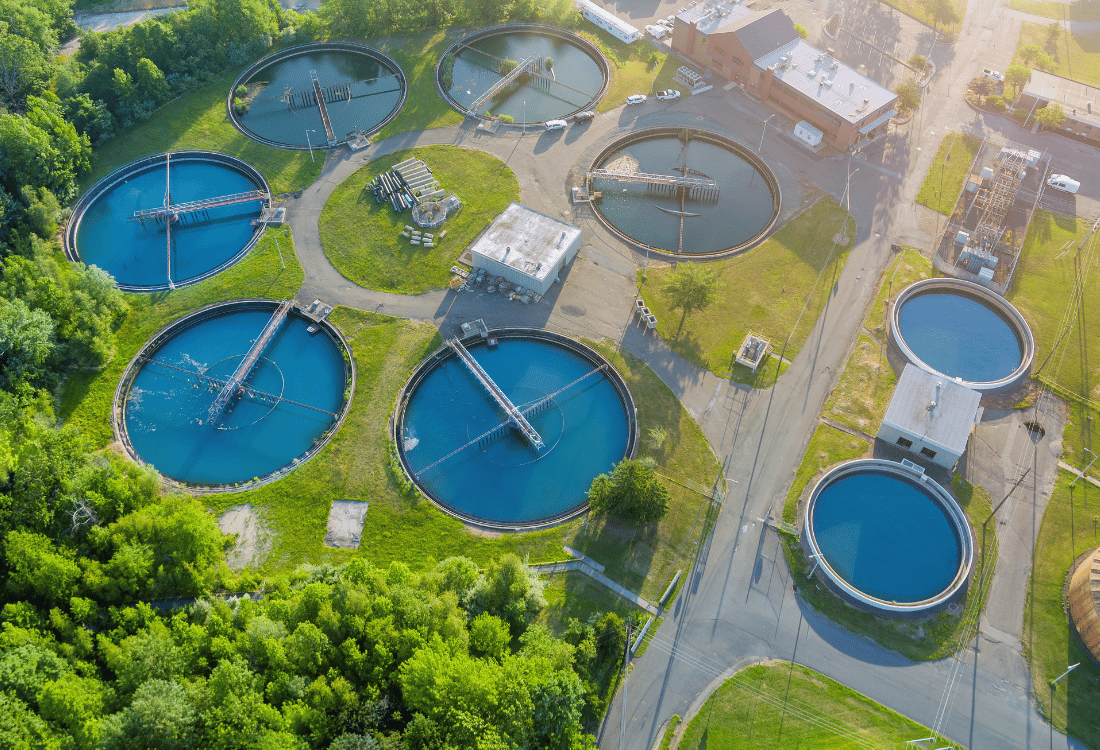

Historically, wastewater treatment has been an energy-intensive process, significantly contributing to high operational expenses and impacting the environment through carbon emissions. In actuality, the process emissions from wastewater treatments account for two-thirds of the total greenhouse gases generated by water and sewage companies, so innovative solutions that minimise energy consumption while maintaining efficient water treatment are in greater demand than ever.

Blog

Subscribe to our blog

Posts By Topics

- Industrial static mixer (26)

- Water Treatment Static Mixers (19)

- Static Mixer (9)

- Pipe Static Mixers (6)

- Channel And Duct Static Mixers (4)

- Pipe Mixers (3)

- Static Inline Mixers (3)

- Chemical Dosing Lances (2)

- Compact Static Mixers (2)

- Gas Dispersion Systems (1)

- Oil And Gas (1)

- Principles of operation (1)

- Sanitary Mixers (1)

- Static Mixer UK (1)

- Static Mixers (1)

Recent Posts

Statiflo:

How Are Static Mixers Installed In The Marine Industry?

Industrial static mixers are invaluable tools in the marine industry, where they are used for a variety of processes including dosing chemicals and dispersing fluids.

How Can A Static Mixer Aid A Ballast Water Treatment System?

Ballast water treatment systems offer numerous advantages, including simple operation, low maintenance requirements, and an environmentally friendly process. However, integrating a water treatment static mixer can further enhance the performance of...

How Could A Static Pipe Mixer Aid In The Desalination Process?

Global water shortages are becoming an increasingly prevalent problem, with at least one-half of the world’s population facing shortfalls for at least one month every year, according to the United Nations.

4 Advantages Of Using Static Mixers In Chemical Manufacturing

Static pipe mixers are devices used to blend fluids within pipelines without the need for moving parts. Instead, they use stationary components, such as baffles or vanes, to induce mixing, relying on fluid flow for homogeneous blending. By altering...

Subscribe to our blog

Posts By Topics

- Industrial static mixer (26)

- Water Treatment Static Mixers (19)

- Static Mixer (9)

- Pipe Static Mixers (6)

- Channel And Duct Static Mixers (4)

- Pipe Mixers (3)

- Static Inline Mixers (3)

- Chemical Dosing Lances (2)

- Compact Static Mixers (2)

- Gas Dispersion Systems (1)

- Oil And Gas (1)

- Principles of operation (1)

- Sanitary Mixers (1)

- Static Mixer UK (1)

- Static Mixers (1)